Piercing is the same as blanking where the cutting line entirely bounds a location. Nevertheless, in puncturing, the reducing line creates the sides of the interior functions of the work surface. The outputs are hand-drafted design drawings and manual computations. Software program such as AutoCAD, SolidWorks, and Tekla Frameworks are preferred instances that carry out both developing and drafting.

Premium: Setting Up Task For Amazoncom

The welding arc and molten pool are immersed in a granular change throughout this process, shielding the weld from the atmosphere. The city terminals' steel components were joined using a SAW, seeing to it they were solid and of the highest quality. This strategy was important in the building of the Delhi https://cpr-depot.ca/about-us/ City, which is just one of the world's biggest city networks, extending over 390 kilometres. India utilized steel to build the Sculpture of Unity, which is the greatest statue on the planet.

Applications Of Architectural Steel In Bridges

Steel Industry Collaboration Ushers in a New Era of Eco-Friendly Manufacturing - OilPrice.com

Steel Industry Collaboration Ushers in a New Era of Eco-Friendly Manufacturing.

Posted: Wed, 08 May 2024 18:00:00 GMT [source]

When searching for a maker for your task, make sure they are licensed under this criterion as it aids to make sure top quality items that fulfill specific requirements. The MetalMaster Xcel is a flexible CNC plasma reducing system understood for its phenomenal accuracy and reduced top quality. It can deal with numerous steel plate densities and is suitable for a variety of steel fabrication applications. This equipment is equipped with automated torch height control to maintain the optimum cutting range from the work surface.

Burrs are developed from shearing, bending, cutting, piercing, and pressing steels. Each of our centers is outfitted with the most up to date modern technology permitting problem cost-free fabrication of structural steel elements. You can feel confident Shaw has the knowledge and capability to finish the architectural steel items https://cpr-depot.ca/news/ of any hefty industrial job. We invite you to experience the extraordinary service and high quality that Superior Rigging and Erecting Co. offers. Regardless of just how complex your project is, we prepare to bring your vision to life with our thorough steel manufacture solutions. You can trust us to be your partner in creating and crafting structures that last a lifetime.

First setting up is done making use of non-permanent joints such as short-term tack welds or bolted links. This process is important to make certain that every component mates with the various other components properly. One of the most crucial steps in steel fabrication projects is welding, and making use of the proper techniques is essential to making sure top quality and endurance. By ensuring that the steel components are adhered correctly, making use of the correct welding procedures can reduce the probability of failure and improve the task's overall high quality. In this comprehensive overview to the steel manufacture process, there is a perfect mix of skilled craftsmanship and technical development. Each step, from selecting the right products to the final examination, plays a role in shaping the top quality of the final steel item.

There are 2 elements which control this end result, specifically the software and the equipment offered in the machine shop. In this regard, a lot of the steel manufacture business favor utilizing cutting-edge technology to keep an eye on the procedure and maintain the efficiency of the process. Along with finishing common tasks, our experienced groups can recognize possible manufacturing obstacles and suggest options that conserve money and time. This competence enables us to complete basically all manufacture refines in-house and offer outstanding lead time control and quality assurance. While not specifically devoted to steel fabrication, Haas VF Series CNC machining centers are extensively utilized for precision milling and exploration of steel parts in the metalworking industry.

Our team believe new and innovative approaches must be constantly developed, boosted and adjusted to meet the needs of the our market. By taking full advantage of modern technology and personnels, we have the ability to deliver architectural steel efficiently and cost-effectively. This process entails covering the surface of a steel part with a layer of zinc to avoid steel from rusting. One of the most typical application method is hot-dip galvanizing where the steel is submerged in a liquified zinc bathroom. In bottom flexing, the work surface is additionally supported at two-point comparable to air flexing. However, lower flexing entails completely pushing the work surface up until its lower side calls the die.

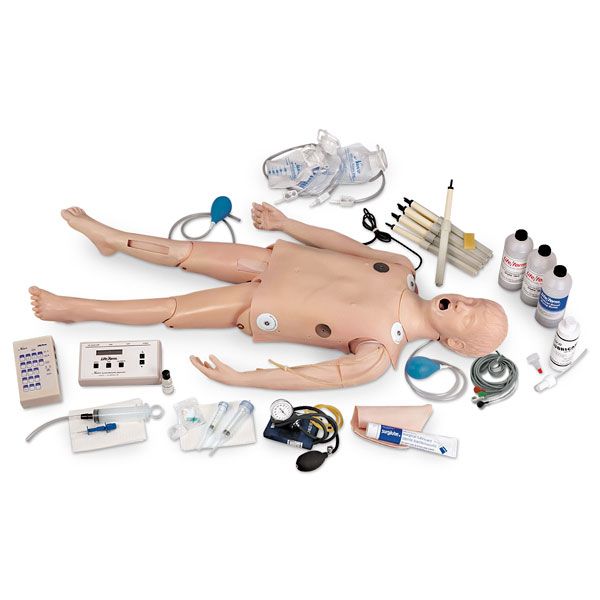

Advanced calculations and modeling can be done which can improve the procedure with quick style models. Among the special steel alloys is stainless-steel that has a selection of usages and can be made in the same way as steel. Like steel, stainless-steel has different qualities each of which is perfect for usage in various applications. Grades 300 and 400 are the most typically utilized with grade 304 being the most preferred and commonly made use of. For heat exhaust applications, stainless-steel grade 321 is excellent because part of its alloy is titanium, which medical mannequin - cpr-depot.ca makes sure really little weld decay.

The placement and movement of the punch depend on the wanted cross-section of the component. This procedure utilizes products with high firmness and rough surfaces for damaging, eroding, scrubing, or wearing the surface area of a work surface. In fabrication, abrasion is performed in a controlled manner which progressively removes excess product from the work surface. This procedure coincides as transforming however the reducing tool steps along the inside surfaces of steel stock.

Heat therapy is an additional procedure that customizes the microstructure of the metal parts. This process can make a product have greater ductility or boosted stamina and solidity. It can additionally ease recurring tensions caused by key production procedures and welding. Planing is a machining procedure that removes excess material by relocating a reducing tool versus a fixed stock in a reciprocating movement. This procedure is made use of for squashing or producing straight contours externally of a huge work surface. This is a reducing process where the supply is revolved while a reducing device is made to relocate laterally past its outside surface areas.

CPR Depot

340 Croft Dr, Tecumseh, ON N8N 2L9, Canada

+15199462222